To conclude ‘A/E50’ objective function produces a consistent,

optimal solution by minimizing errors and selecting well-

distributed

GCP

s. It is also found to be resistant to 50 percent

of errors in the data and

GA

converges to solution mostly

between 20 generations and 40 generations even with errors

in the data sets.

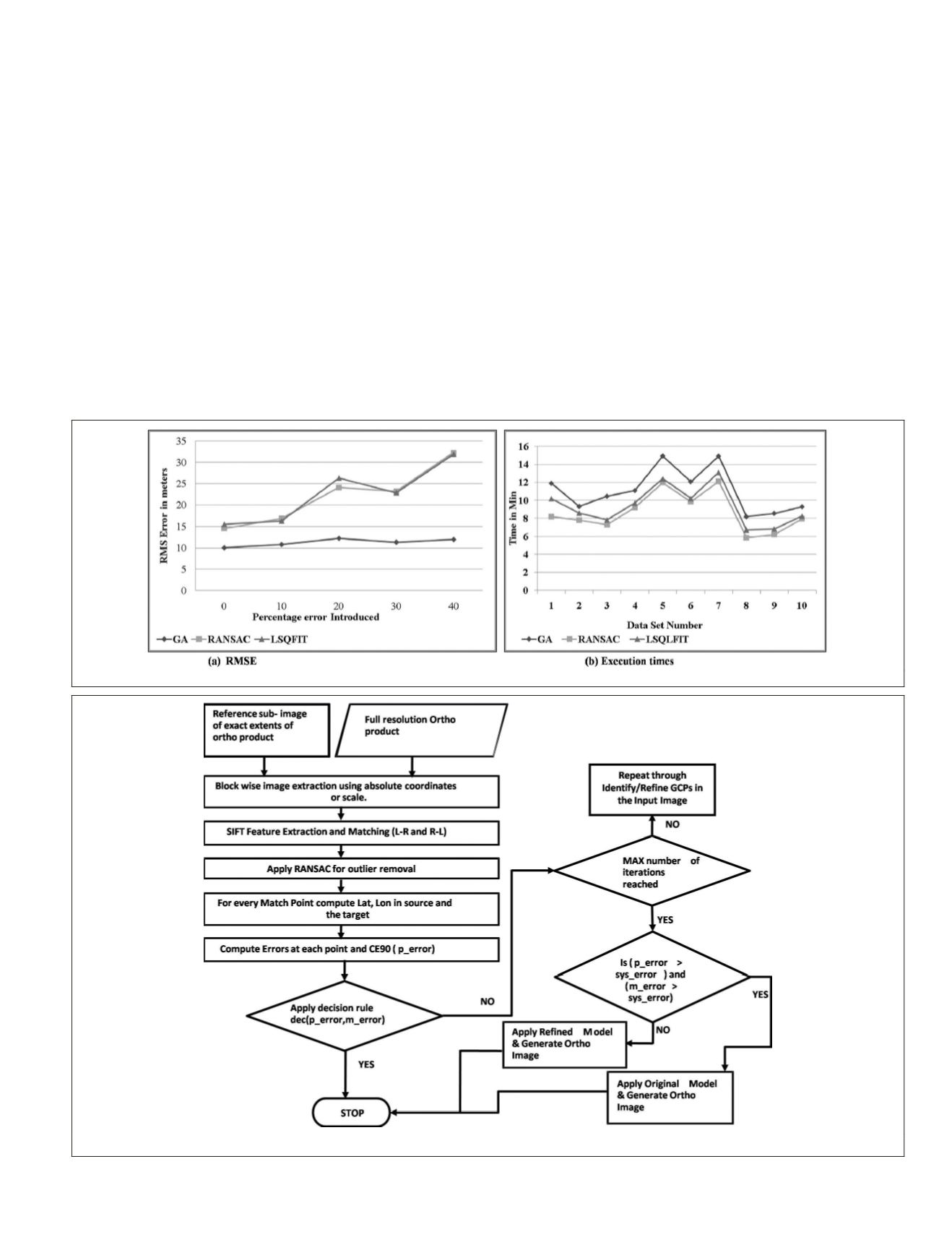

Comparison between GA, RANSAC and Iterative LSQ

The same experiment previously done is compared with

non-

GA

based methods implemented in

RANSAC

and itera-

tive LSQ Fit; the results are depicted in Figure 6. Figure 6a

indicates that even as the percentage of errors increased, the

GA

produced consistent results by generating an accurate

ortho-product as compared to other methods. The product er-

rors were found to be around 10 m with proposed

GA

method-

ology, while

RANSAC

and Iterative LSQ Fit failed to generate

accurate ortho-products; the error increasing to as high as 35

m in the final product when 40 percent of points were errone-

ous. Figure 6b depicts the running times of

GA

,

RANSAC

, and

Iterative LSQ. It is well known that evolutionary methods

take more time compared to deterministic and heuristic based

approaches. It was observed that

GA

took two to four minutes

more compared to the other approaches. We believe that this

additional time used may be easily compromised as the final

product generated is assured of better accuracy.

The conclusion of this experiment is that with a fractional

increase in time taken, the proposed

GA

method produces an

accurate product as compared to

RANSAC

and Iterative LSQ fit.

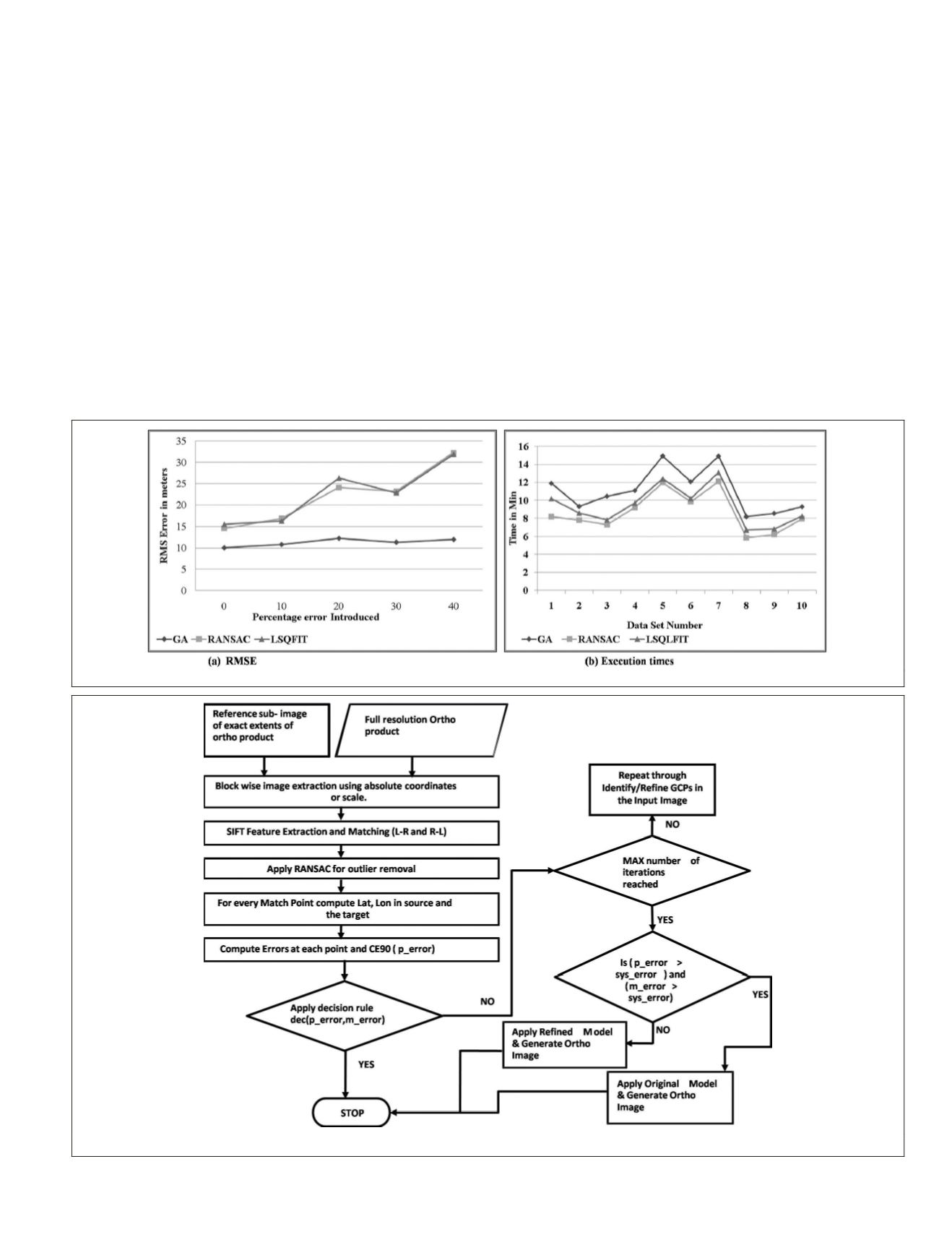

Decision Rule-based Product Evaluation

After the successful evaluation of

RSM

using the

GCP

s identi-

fied by

GA

, the ortho-product is generated automatically using

the standard ortho-rectification procedure as shown in block

$

in Figure 1. The proposed methodology of product evaluation

is depicted in Figure 7. It also describes the control loop back

structure for re-generating the product if error in the product

is more than the acceptable limits.

Product evaluation involves identifying tie points in both

the reference image and the ortho-image. To identify the tie

points, we again propose

SIFT

-based feature matching, as was

previously done in the “checkpoint identification section.”

Here, the first stage of transformation estimation is by-passed

Figure 6. Comparison of proposed GA method with RANSAC and Iterative LQS Fit for RSM refinement.

Figure 7. Product evaluation and Control Loop back mechanism.

PHOTOGRAMMETRIC ENGINEERING & REMOTE SENSING

May 2016

383