requirements this fact will be reflected in their metadata (re-

member the sentence “This map complies with

NMAS

”). But a

sampling plan establishes and makes explicit to both producer

and acquirer (user) clearer than a

PAAM

the conditions of the

process: definition of lot, lot size, sampling method, sample

size, and producer’s and user’s risk (described below), etc.

The decision from an investigated sample on whether

or not a lot satisfies stated requirements can be carried out

through hypothesis testing (achieving a pass/fail decision).

A statistical hypothesis is a statement about a probability

distribution function or about the values of the parameters

of a probability distribution function (parametric case). In

statistical testing two alternatives are always considered: (a)

H

0

: the so-called Null Hypothesis, and (b) H

1

: the so-called

Alternative Hypothesis. For example, in relation to

PAAM

s, the

EMAS

applies two tests together (bias tests and variance tests)

to each positional coordinate (X, Y, and Z).

Since sampling is a random procedure, two kinds of errors

may be committed. If the

H

0

is rejected when it is true, then a

type I error (

α

) has occurred. If the

H

0

is not rejected when it is

false, then a type II error (

β

) has occurred. The Type I error is

called producer’s risk because it denotes the probability that

a good lot/product will be rejected, or the probability that a

process producing acceptable values of a particular quality

characteristic will be rejected as producing unsatisfactory

ones. The Type II error is called user’s risk because it denotes

the probability of accepting a lot/product of poor quality.

Sometimes it is more convenient to work with the power of

the test (Montgomery, 2001), which is the probability of cor-

rectly rejecting

H

0

(Power = – β = P{reject H

0

}).

In relation to the size

n

of the sample when testing statisti-

cal hypotheses, the general procedure is to specify a value for

α

and then to design a test procedure so that a small value of

β

is obtained. Thus the producer’s risk is directly controlled

or chosen by

α

;

and the user’s risk is generally a function of

n

and is controlled indirectly. The larger the size of the sample,

the smaller the user’s risk (Montgomery, 2001). In general,

PAAM

s provide a sample size in an attempt to ensure the pro-

ducer risk (remember the sentence “at least 20 points”). This

suggested sample size is not related to the size and variability

of the population and does not ensure that user risk will be

kept under a specific threshold. Only recent proposals, such as

the new

ASPRS

positional accuracy standard (

ASPRS

, 2015), re-

late the required sample size to the size of the project area. In

ISO

2859 the size

n

is related to lot size and established risks.

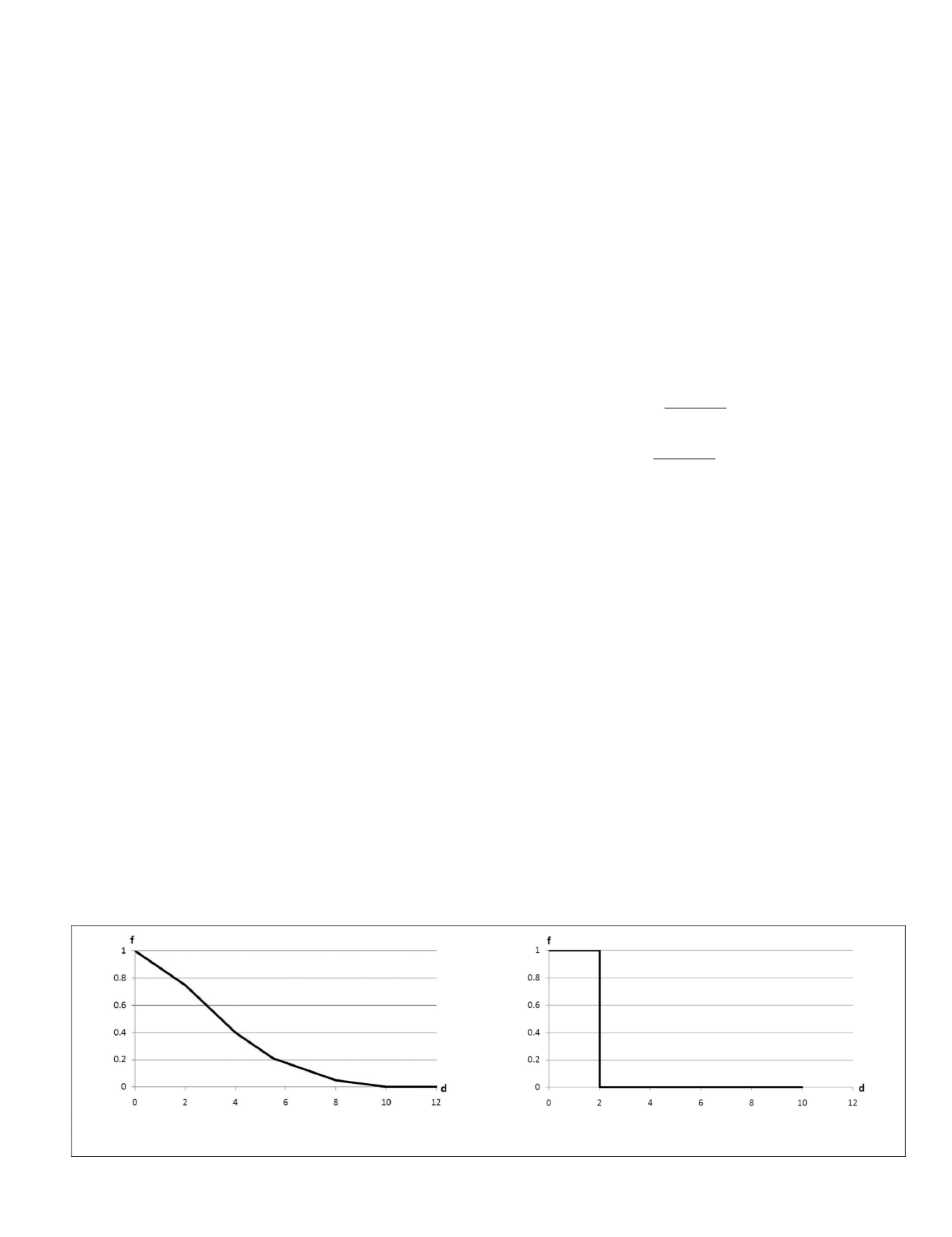

Acceptance plans are summarized by means of Operating

Characteristic curves (

OC

curves) (Figure 1).

OC

curves plot

the probability or frequency

f

of accepting lots in the Y-axis

versus the percent defectives

π

d

on the X-axis. When it comes

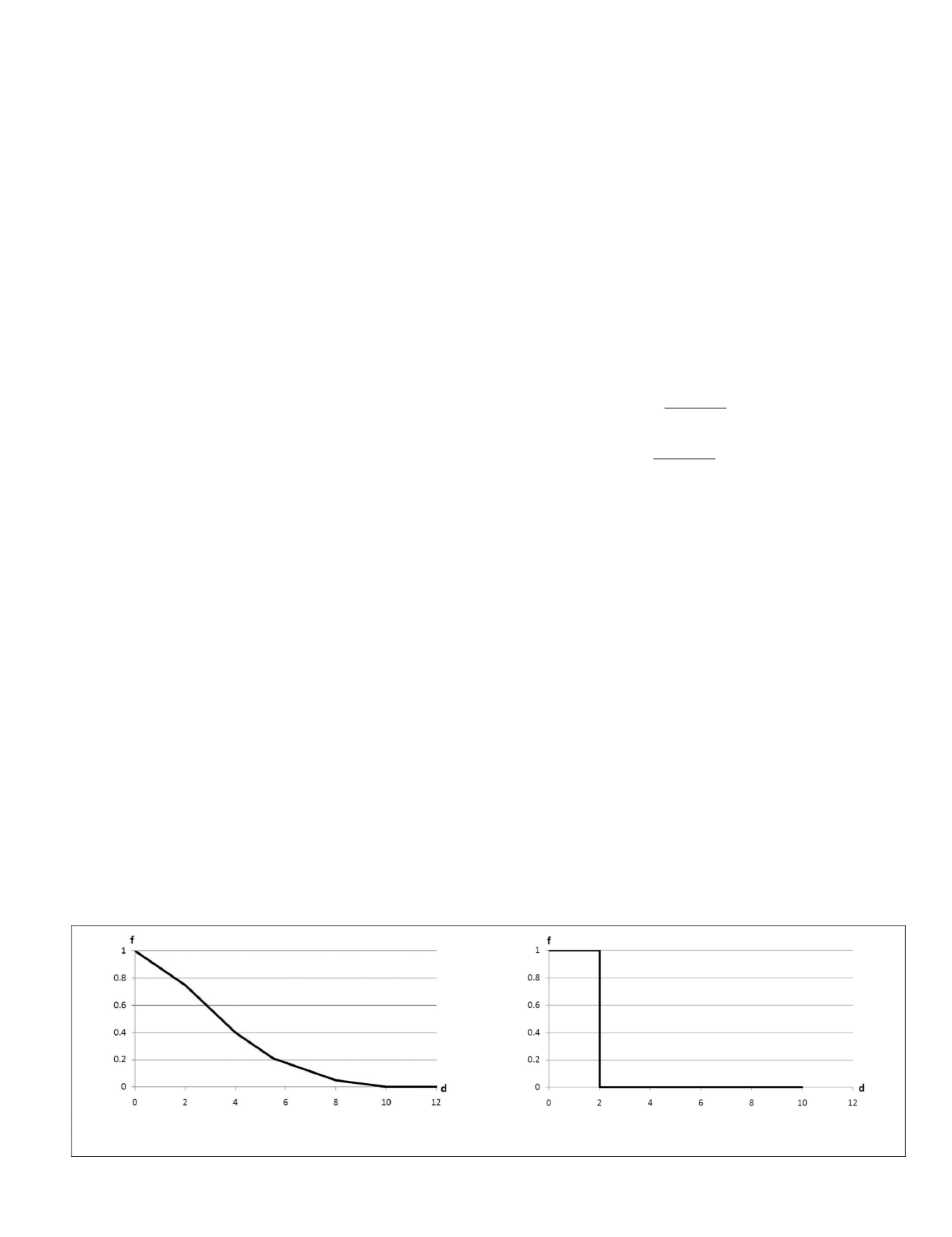

to 100 percent control

OC

curves represent an ideal case and

have a step shape (Figure 1a). Good lots are always accepted,

and bad lots are always rejected. Because of the sampling

randomness, actual

OC

curves are not step-shaped (Figure 1b).

Thus, an important feature of a sampling plan is how it dis-

criminates between lots of high and low quality. The ability of

a sampling plan to discriminate between lots of high and low

quality is described by its

OC

curve. A sampling plan cannot

provide perfect discrimination between good and bad lots be-

cause of the randomness of the sampling, so some low-quality

lots will inevitably be accepted and some high-quality lots

will inevitably be rejected. The degree to which a sampling

plan discriminates between good and bad lots is a function of

the steepness of its

OC

curve: the steeper the curve, the more

discriminating the sampling plan.

A common approach to the design of an acceptance sam-

pling plan is to require that the

OC

curve pass through two

designed points (Montgomery, 2001). Usually the two points

used are those corresponding to the user and producer risks.

Assuming that a binomial approximation is appropriate, the

sample size

n

and the acceptance number

c

are the solution to

the equations Equation 1 and Equation 2:

1

1

0

1

1

− =

−

(

)

−

=

−

∑

α

d

c

d

n d

n

d n d

p p

!

!

!

(

)

(1)

β

=

−

(

)

−

=

−

∑

d

c

d

n d

n

d n d

p p

0

2

2

1

!

!

!

(

)

(2)

where

α

is the Size of Type I error (producer’s risk),

β

is the

Size of Type II error (user’s risk),

n

is the Sampling size,

c

is the Acceptance number,

d

is the

Number of defectives in the sample,

p

1

is the Probability of producer risk for the point, and

p

2

is

the Probability of user risk for the point.

Equation 1 and Equation 2 are nonlinear and there is no

simple direct solution. Duncan (1986) gives a description of

some techniques for solving this system of equations: the Lar-

son binomial nomograph can be used as a graphical approach

and Kapusta

et al

. (2011) propose a mathematical model for de-

signing specific acceptance plans and provide a Matlab

®

code.

ISO 2859-1 and ISO 2859-2

ISO 2859-1

Acceptance sampling was first introduced during World War

II to determine whether to accept or reject a given batch of

military supplies. A cost (and time) saving method was needed

which would not require 100 percent of elements to be tested,

while still maintaining an adequate quality level. Dodge (1969)

identifies July 1942 as the birth of this standard under the title

of

Standard Inspection Procedures

. It achieved the status of De-

partment of Defense Standard,

JAN-STD-

105, with the develop-

ment by the Statistical Research Group of Columbia University

(a)

(b)

Figure 1. An operating characteristic curve: (a) operating curve for an ideal situation, and (b) operating curve for a sampling situation.

PHOTOGRAMMETRIC ENGINEERING & REMOTE SENSING

August 2015

659