developed on the population, not on a parameter of the popu-

lation. This idea is illustrated in Figure 5.

The

BaM

represents the error behavior in the population,

so given a metric tolerance

Tol

(here being the maximum po-

sitional error in meters one is willing to accept), the percent-

age of error cases greater than the desired

Tol

is

π

. In other

words,

Tol

is the value corresponding to the

1-

π

percentile. In

a control sample of size

n

, the fact that the error

E

i

in element

i

verifies

E

i

>Tol

is defined as a fail event in a binomial sense

(we call it a “positional defective: in this case). The

BiM

con-

sists of counting the number of positional defectives,

f

. This

test follows a Binomial

B(n,

π

)

distribution, and the probabil-

ity of positional defectives is:

P F f F B n

n

k

k f

n

k

n k

≥ →

( )

=

−

(

)

=

−

∑

,

π

π

π

1

(3)

where

π

=

P

[

E

i

>Tol

] is the probability (

BaM

model) that a

point

i

has an error value,

E

i

, greater than the specified toler-

ance,

Tol

;

F

is the random variable “number of defective

points in a sample of size

n

”;

f

is the number of sampling

points that are defective (that is to say, their ECM is greater

than

Tol

;

n

is the sampling size;

k

is a summation index (we

sum all probabilities between

k

=

w

and

k

=

n

;

P

[

A

≥

b

|

A

(

θ

)]

is the operator “probability”– that is to say, it indicates the

value of the probability that the random variable

A

takes a

value greater than or equal to

b

when the random variable

A

follows a probability distribution

with parameter

θ

; and

B

(

n,

π

) is the binomial distribution with parameters

n

and

π

.

The null hypothesis is:

H0: The

SDS

is adequate. Given a signification value (

α

) (type

I error or producer’s risk), it means that errors are distributed

according to the

BaM

and only

π

percent of cases are greater

than

Tol

versus

H1: The

SDS

is not adequate.

Now the question is how to use this model in conjunction

with

ISO

2859-1. The answer is relatively easy because this

method is based on counting fail events (we call them here

“positional defectives”) and counting of defectives/defects

is what we need in order to apply

ISO

2859-1. Given a ran-

dom sample taken from a lot, the idea is to consider that an

element is of good quality if its error is less than the toler-

ance and that an element is a positional defective if its error

is greater than the tolerance. But some additional explana-

tions are needed. In positional controls, we are accustomed

to working with root mean squared errors or with standard

deviations and with confidence intervals in order to express

the positional accuracy of a data set. But in

ISO

2859-1 we

must use another parameter in order to express the quality of

a lot, the previously defined

AQL

. The preferences of the user

are now expressed by the pair

{Tol,

AQL

}

: the desired metric

Tol

and the upper limit of the percentage of cases that are

greater than this tolerance and which he is willing to tolerate

in accepted lots.

Nevertheless, there is a relation between both

Tol

and

AQL

and this relation comes from the

BaM

. The relation is that

AQL

=f(

π

)

, where

π

is the same as previously defined. Looking

at the

AQL

values (…0.65 % , 1 % , 1.5 % , 2.5 % ...) proposed

in

ISO

2859-1, it is clear that the tolerance must be situated

on the right side of the

BaM

model and it must be selected in

order to allow only small percentages of positional defectives.

For the producer to obtain a high acceptance of his lots, he

must work with processes that, for the same

Tol

, ensure that

the actual defective percentage is less than the

AQL

. This can

be stated in another way: given a

BaM

and a tolerance value

Tol

, the

AQL

value should be chosen to be greater than

π

. This

explanation has been developed considering that

AQL

and

π

are subrogates of

Tol

, but the same is also valid if

Tol

is con-

sidered a subrogate of

AQL

and

π

.

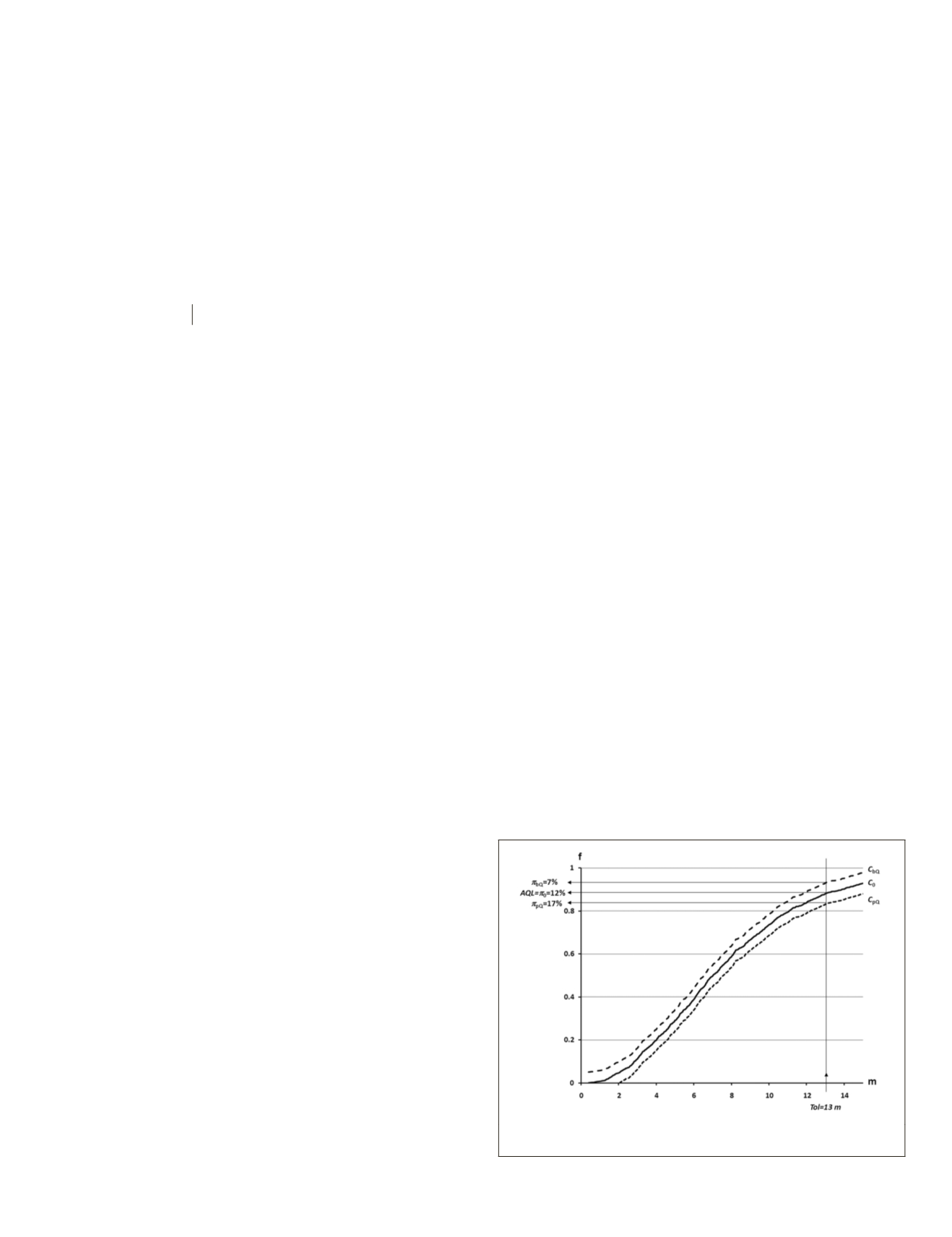

Figure 6 shows these ideas graphically. Let us consider a

BaM

represented by the solid curve labeled with

C

o

; if

Tol =

13 m through the

BaM

we obtain that

π

o

=

12 percent

,

meaning

that 12 percent of position errors are greater than 13 m. If we

want

AQL

to =

π

o

=

12 percent , it means that in order to assure

a high average of accepted lots, the producer must be able to

supply data with some better positional quality, which means

that the actual

BaM

of the product must be a curve over the

C

o

; for example, the curve labeled with

C

bQ

. Because

π

bQ

=

7

percent

<

π

o

=

12 percent, this situation assures a high level of

acceptance. But if the data supply is of a poorer quality than

demanded, the situation can be shown graphically by the

curve labeled

C

pQ

. Because

π

pQ

=

17 percent

>

π

o

=

12 percent

this situation assures rejections and the stopping of the sup-

ply by means of applying

ISO

2859-1 switching rules.

The above example is based on an empirical

BaM

(observed),

but we can also work with parametric models. For example,

for a specification of a positional error of 1 m in each coordi-

nate (planimetric error of 2.4477 m for 95 percent confidence),

we have

Tol

= 2.4477 m and

π

= 5 percent, so the

AQL

should

be slightly higher than 5 percent; and it means using tabulated

values of

ISO

2859-1 that

AQL

= 6.5 percent, so that in this case,

the control specification is (

Tol

= 2.4477 m,

AQL

= 6.5 percent).

Also, the presence of bias and outliers is related to the

AQL

by means of the

BaM

. The situation is very simple; in the case

of bias there is a right shift of the entire

BaM

. This means that:

• For the same initial Tol, the

π

value increases dramati-

cally and as a consequence

AQL

increases.

• For a given

AQL

the Tol must be increased.

In the case of outliers, there is down shift of the right tail

of the

BaM

. This right tail is the part of the model that accu-

mulates frequency coming from the largest error values. This

down shift of the right tail is equivalent to a partial right shift

of the base model. In this case we must pay attention to the

position of the

Tol

with respect to the right tail of the model

affected by the outliers. If the

Tol

is not in the affected tail,

the situation is similar to the prior one; but if the

Tol

is in the

affected tail, the situation is totally equivalent to a general

shift of the base model by bias.

It is relevant to note that the presented method is also valid

when the

BaM

is unknown. By taking the user’s preferred values

{Tol,

AQL

}

and by counting the positional defectives in the

sample, this procedure can be applied protecting the user com-

pletely. Here the problem is for the producer if the actual

BaM

of

Figure 6. Relations between metric tolerance (

Tol

), AQL and π in a

Base Model.

PHOTOGRAMMETRIC ENGINEERING & REMOTE SENSING

August 2015

663